Before laoding the machine in the container, we clean the machine first cover with a film.

fix the machine stable tighty by Steel wire rope in the container, thus, for the machine safe, no moving.

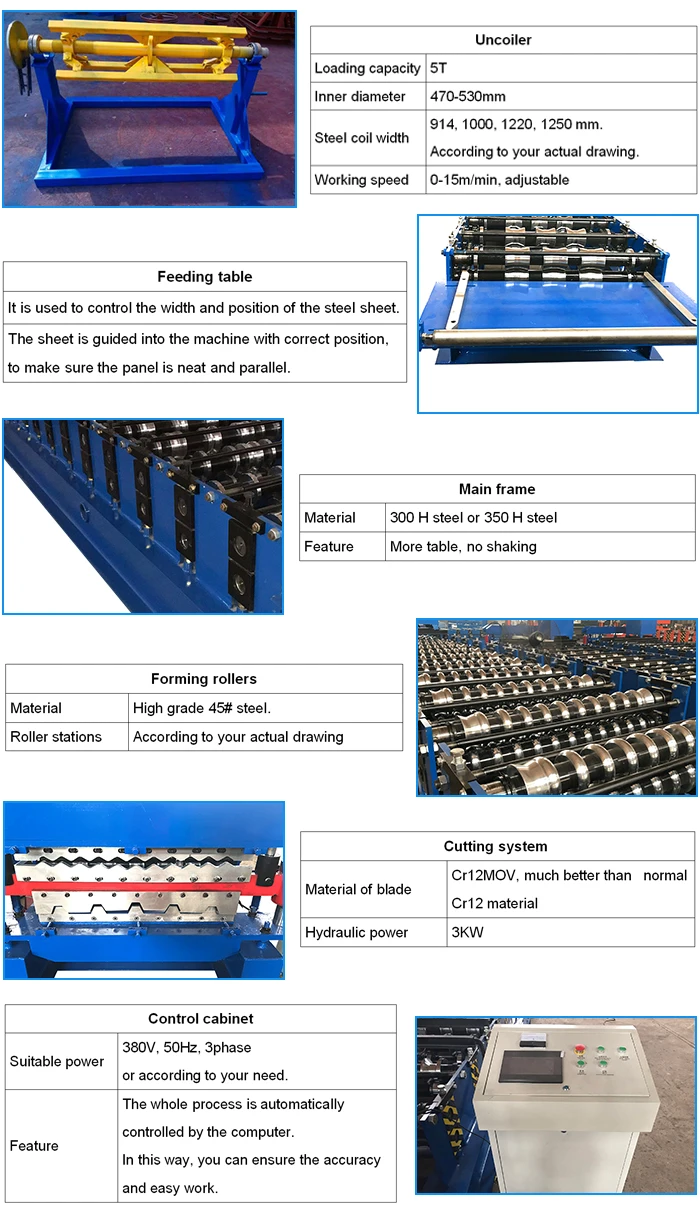

This machine takes GI/PPGI as raw material, through a series steps can produce the metal roofing sheets.

The inverter controls the motor speed, the PLC system controls length quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

1 | material of input sheet | aluminium/galvanized steel/ colored steel |

2 | feeding width | 1250mm |

3 | effective width | 1050mm |

4 | material thickness | 0.3-0.8mm |

5 | main motor power | 3kw |

6 | hydraulic pump power | 3kw |

7 | forming step | 13 steps |

8 | diameter of shaft | 70mm |

9 | main frame | 350H steel |

10 | roller material | 45# steel with chrome |

11 | cutting knives material | Cr12 |

12 | control system | PLC control system with inverter |

13 | working speed | 8-12m/min |

14 | machine size | 5.8*1.3*1.3m |

15 | machine weight | about 2.5 tons |

16 | voltage | 220v, 3phase, 60hz |

Before laoding the machine in the container, we clean the machine first cover with a film.

fix the machine stable tighty by Steel wire rope in the container, thus, for the machine safe, no moving.